Essential business challenges

The food industry must meet high standards: ensuring food safety, maintaining complete product traceability, adapting to changing market demands, and controlling costs. These requirements are driven by strict regulations and international standards:

- IFS Food v8 (International Featured Standards Food, version 8): a certification framework for food safety and product quality.

- BRCGS 9 (Brand Reputation Compliance Global Standards, version 9): a global standard for managing food safety.

- HACCP (Hazard Analysis Critical Control Point): a method for analyzing and controlling hazards at every stage of production and distribution.

These standards demand flawless traceability, rapid recall capabilities, and impeccable documentation at all times.

End-to-End Traceability: From receiving to plate

In SmartQuality, each pallet is identified upon receipt: date, certificate, transport temperature, potential allergens, and more. All information is centralized in an audit trail compliant with IFS and BRCGS standards. Thanks to this level of granularity inherited from biotech, a quality manager can, in just a few clicks, trace the journey of a bag of cocoa all the way to the brownie delivered to the distributor—delivering the promise of flawless traceability.

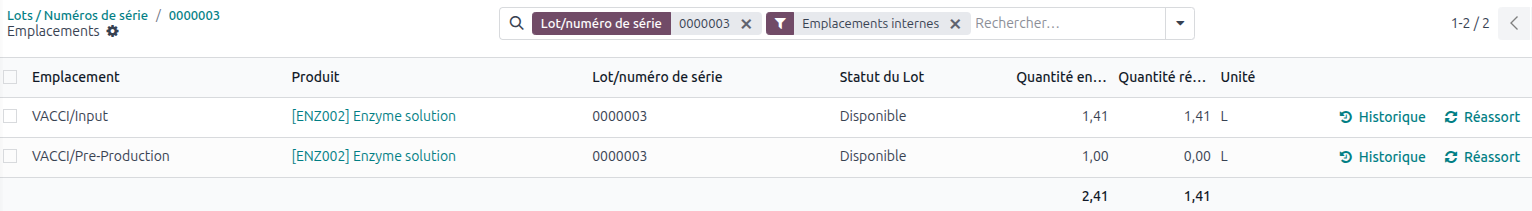

(Location report allows tracking of a lot’s location, quantity, status, and history.)

Quality and laboratory without borders

SmartQuality natively integrates a LIMS (Laboratory Information Management System), a tool that automatically generates a sampling plan based on supplier history and observed risk levels. Each lot is thus tested before storage or shipment, in line with IFS and BRCGS expectations. Analysis results release or block a lot in real time, preventing both stockouts and unnecessary overstock.

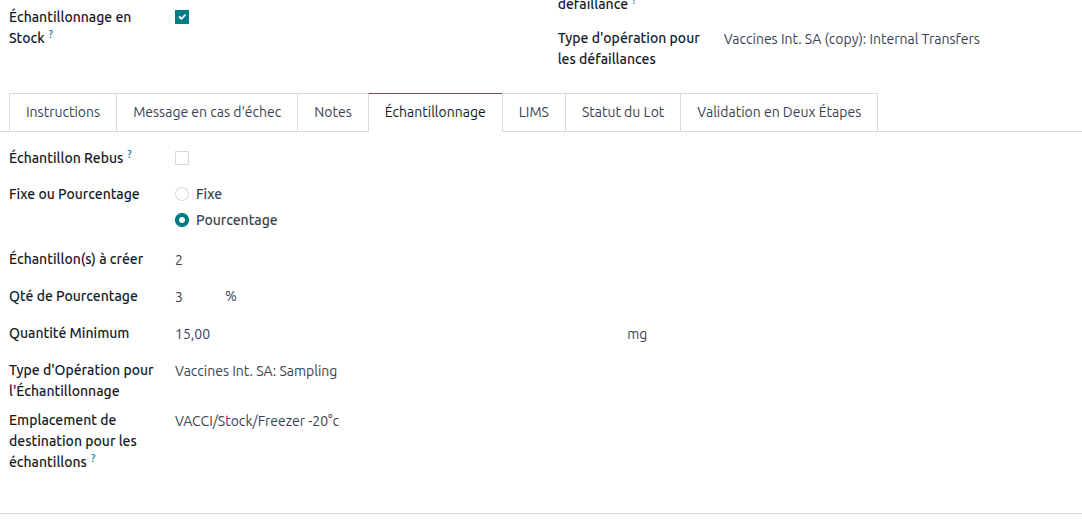

(Automatic sampling plan configuration—each plan can be customized by product or product category.)

Controlled recalls: Thirty seconds that matter

Smart Biotech allows users to retrieve all necessary information in under a minute with immediate precision. The system also enhances communication between different applications, making searches faster and more seamless. Built-in filters provide instant access to the exact data needed, enabling users to achieve precise results quickly and effortlessly.

Drive your performance, secure your growth

Facing increasing regulatory requirements and unpredictable markets, food industry manufacturers need a reliable, flexible, and comprehensive tool. Smart Quality (Smart Biotech) delivers concrete, field-tested solutions: every feature has been validated, and every piece of user feedback has contributed to the improvement of the solution.

To see how these innovations can transform your industrial operations, request a demonstration and step into the next stage of your performance: https://idealis.solutions/contactus.

Why Smart Quality (Smart Biotech) meets the specific needs of the Food Industry